D.W. CLARK

Advanced Castings

Advanced Alloys

Delivering complex and specialty alloy castings from prototype through production

Welcome to D.W. Clark

D.W. Clark is as much a service company as we are an alloy castings manufacturer. We build partnerships based on our goals of being the best at delivering the highest quality castings and solving the most challenging needs. We are proud that our castings can meet an array of NDT measures and are utilized in systems supporting energy, defense, aerospace, transportation, flow control, and other critical applications around the world. While making thousands of unique castings every year through traditional casting as well as 3D mold printing casting techniques, our success is ultimately measured by one goal: customer satisfaction.

Featured Castings

Some of the most important systems, from water infrastructure to power generation and renewable energy, are made possible with alloy castings. As a proud centrifugal casting and sand casting manufacturer that supplies parts to these systems and many other critical applications, D.W. Clark manufactures high-end castings that demand excellence—meeting non-destructive testing standards in over 200 alloys including ni-resist—from prototype to full production.

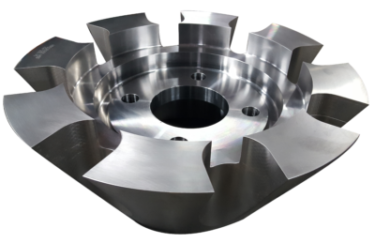

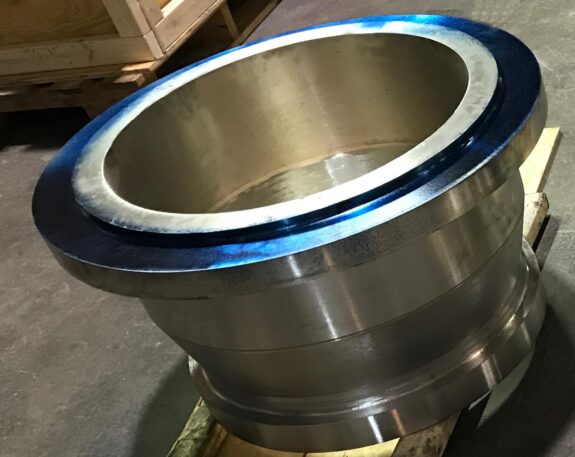

Centrifugal Castings

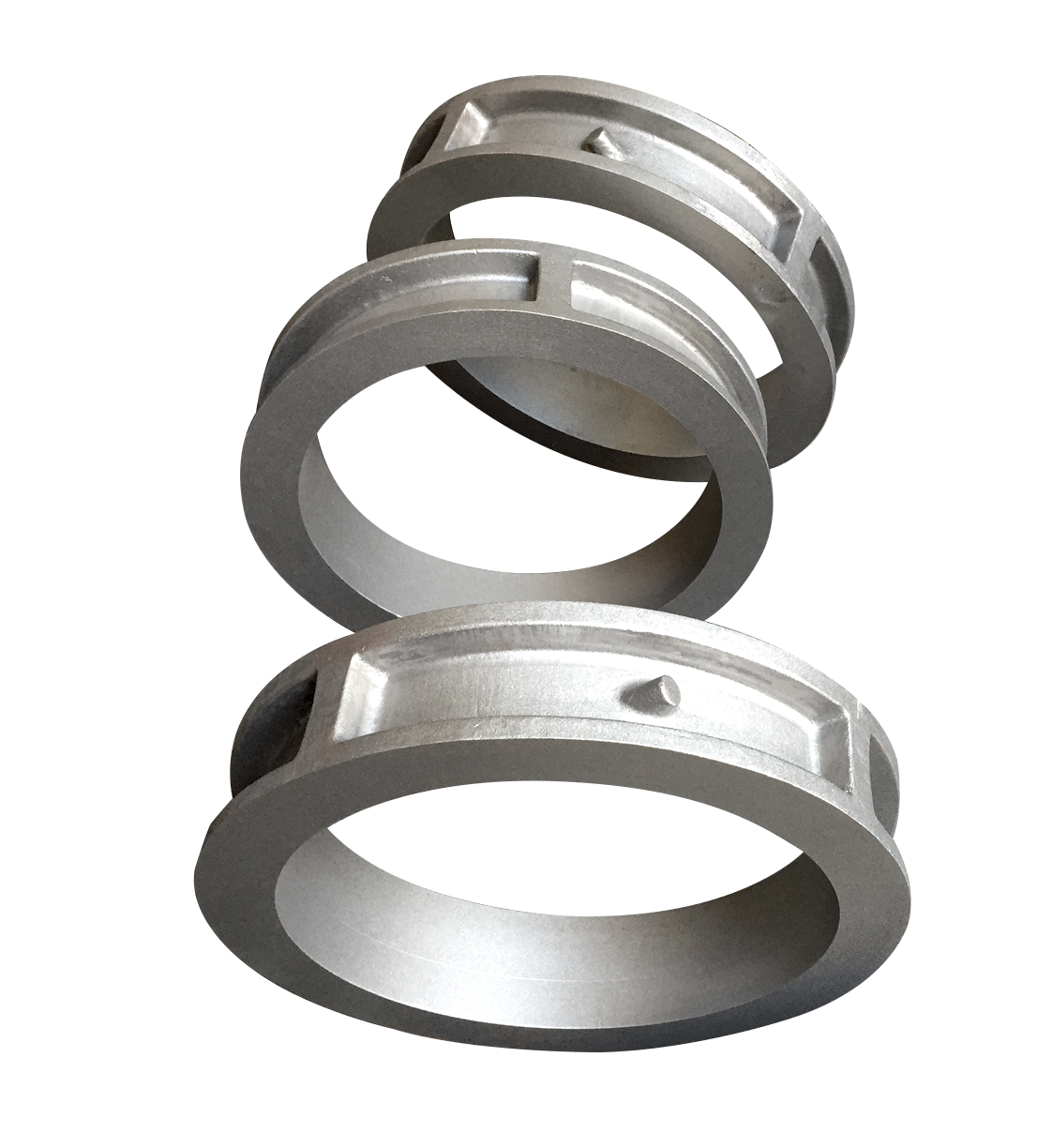

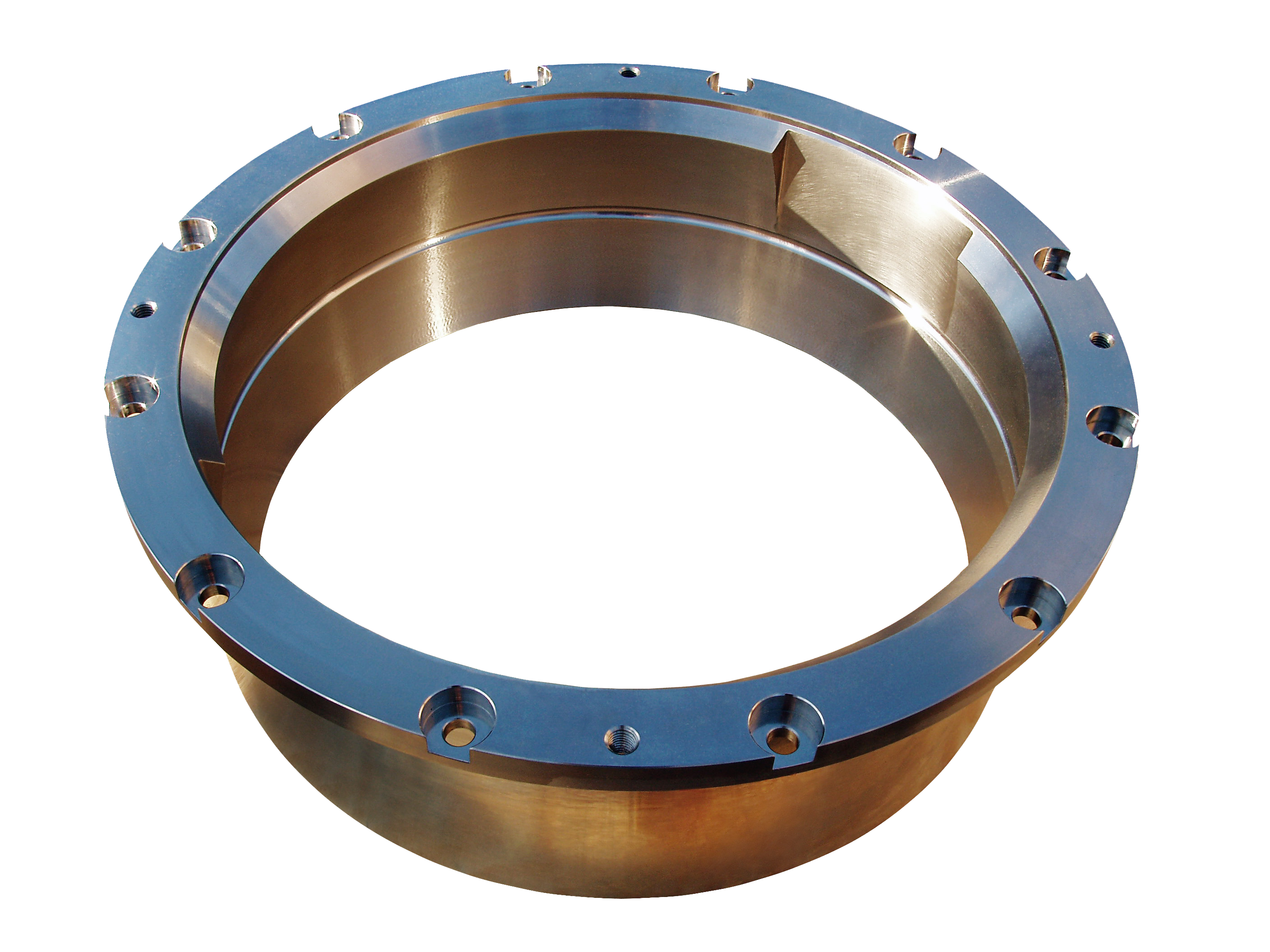

Formed using centrifugal force to cast under pressure and solidify directionally, the centrifugal casting process provides exceptional soundness and material quality. A full range of alloys can be produced, from stock-sized rings and tubes to advanced features with flanges, bosses, ribs, through-holes and more, shaping the outer diameter of a part.

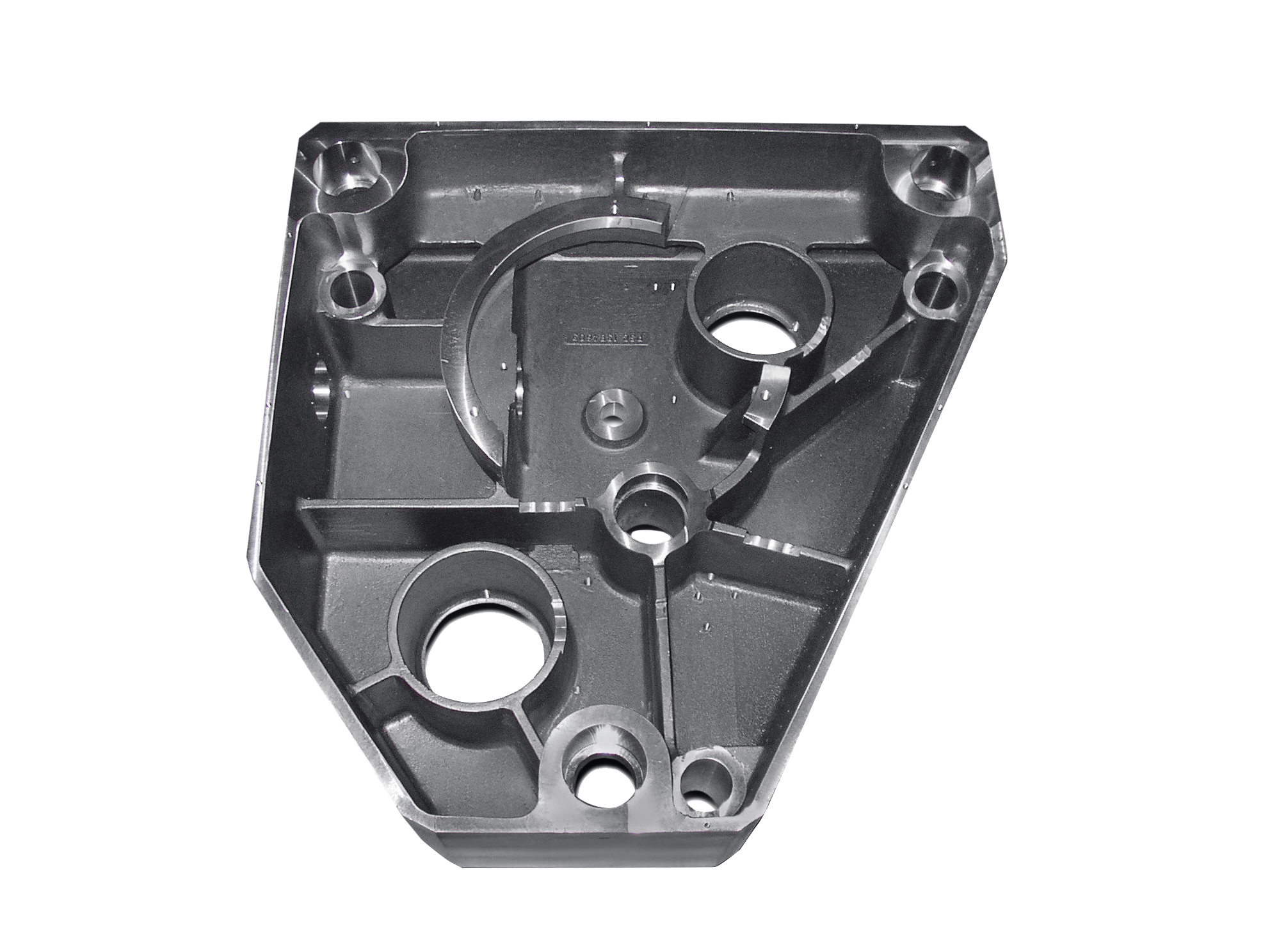

Sand Castings

Sand casting provides advantages in versatility with alloy, shape and size flexibility combined with production scale capabilities that can cost-effectively deliver low to medium production volumes for demanding applications. Castings are engineered for each customer with the latest modeling and simulation technology.

Precision Sand Castings

Leading the way in casting technology and capability, precision sand casting leverages modeling and 3D printed molds to produce complex and dimensionally precise castings with zero expensive tooling costs. With the latest large format 3D mold printer expansions, D.W. Clark has the most extensive 3D mold printing casting capability for alloy castings.

ALLOYS

STAINLESS

STAINLESS

STEEL

STEEL

NICKEL BASE

NICKEL BASE

IRON

IRON

NON-FERROUS

NON-FERROUS

COBALT

COBALT

INDUSTRIES WE WORK IN

Defense

Propulsion components, valves, pumps, bearings, wear rings, weapon handling & shipbuilding

Aerospace

Forming dies, mandrels, piston rings & sleeves

Turbine Engine

Casings, inlet guides, diffusers, turbo volutes, impellers & seal rings

Energy

Fuel cell structural, solar collector components, bushings, rings, seals/wicket gates for hydro power & nuclear plant components

Valve and Flow Control

Valve bodies, fittings & flanges in hundreds of combinations of type, size & alloy

Pumping Systems

Impellers, pump casings & wear rings

Processing Equipment

Steel mill, paper mill, mixing blades, packaging, bottling & medical system structural components

Marine

Propulsion, shaft sleeves, valves & general shipbuilding components